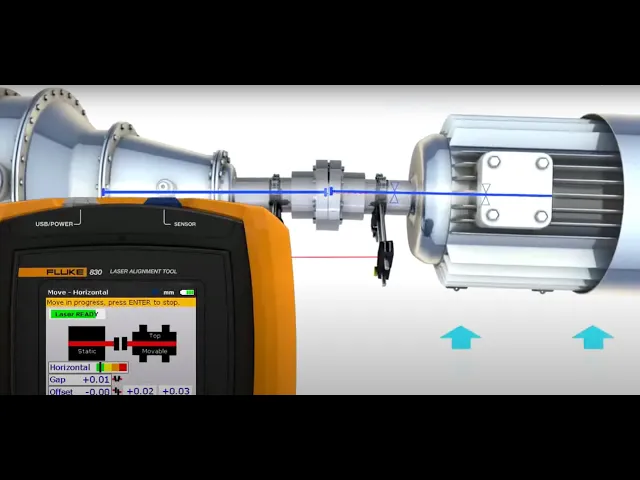

FLUKE 830 Laser Shaft Alignment Tool

This product is now obsolete. CLICK HERE to find out more about the FLUKE 831 Laser Shaft Alignment Tool (the product which has superseded the 830).

The FLUKE 830 uses single-laser measurement technology, compass measurement mode for flexible, reliable, and repeatable measurements and dynamic machine tolerance. The tool comes complete with unique extend mode to handle gross misalignment and a intuitive guided user-interface.

Why is shaft alignment so important?

Up to 50% of the damage to rotating machine is directly related to misalignment.

Misalignment leads to:

- Premature bearing, seal, coupling and shaft failures

- Looseness of foundation bolts and base-plates

- High vibration and temperatures

- High power consumption

- High maintenance costs

Benefits of precision alignment:

- Increase availability

- Increased productivity

- Increase lifetime

- Optimised energy efficiency

- Lowering operating costs

FLUKE 830 Key Features:

- Easy to use tool for precision alignment of rotating shafts

- Features single laser measurement technology to reduce errors from backlash and enhance accuracy

- Provides an intuitive, guided user interface to quickly and easily complete machine alignments

- Includes compass measurement mode to enable flexible, reliable, and repeatable measurements using an activated electronic inclinometer

- Includes a unique ‘All-in-One‘ result screen that shows both coupling results and vertical and horizontal feet corrections, making it easy to take corrective action

- Features a dynamic machine tolerance check that provides continuous evaluation of alignment adjustments so you know when your machine is in the acceptable range

- Offers unique extend mode to handle gross misalignment by virtually increasing laser detector size

- Provides auto save and resume capability to ensure your data is there when you need it

So why choose the FLUKE 830?

When uptime matters, picking the right tool is critical; many tools are simple, but they can take a lot of time to re-learn how to use them and to remember what the numbers mean - especially if it’s been a long time since the last alignment was performed. You need a tool that walks you through the steps so that you can get back to running the plant. With the FLUKE 830 Laser Shaft Alignment tool evaluating alignment can be done in three simple steps:

Unlike using traditional straightedge method or dial indicators the FLUKE 830 performs the complicated alignment calculations for you, meaning you‘ll have the answers you need to quickly align your machine and get your plant up and running fast. An enhanced user interface provides easy to understand results that don‘t require extensive alignment knowledge and the unique ‘All-in-One‘ result screen that shows you both coupling results and feet corrections (vertical and horizontal) in real terms making it easy to take corrective action.

A great alternative to traditional shaft alignment measurements is a laser shaft alignment system. Laser shaft alignment systems reduce the potential for human error and can have resolutions as good as 1/1000 mm or 1 micron (0.00004 in).

Since machine downtime is costly, test repeatability is critical. The FLUKE 830 uses a patented single laser precision alignment system that provides accurate and repeatable measurement results so you can be assured you‘re addressing misalignment problems properly.

▶ Video: FLUKE 830 Laser Shaft Alignment Tool: Why Precision Alignment?

What comes with the FLUKE 830?

- FLUKE 830 Laser Alignment Tool

- Laser sensor with integrated wireless

- Laser prism

- Chain-type mounting bracket with 150 mm support posts (2x)

- 300 mm support post (4x)

- Micro fibre cleaning cloth

- PC cable

- USB drive and drive cable

- Tape measure

- Power adapter

- Instruction kit and carrying case